With the movement out of the clock it can be fixed. If all else fails, and it’s a chain driven clock, you would need to cut the chain in half, or break a link, to take the movement out of the clock. The weight will then come down enough to run the clock. The leader will tick tock faster as you pull down some on the weight. This will make it tick tock faster than if the pendulum was on. All it will have is the pendulum leader hanging on the back of the movement. If this does not work, take off the pendulum. See if it starts running on its own when letting go. Try pulling down some while swinging the pendulum. This is the hardest weight to deal with out of the three. The time weight is the center weight which can be light or heavy depending on bob size. This will hopefully be enough to activate and run the chime on its own. When you advance the time and make it chime, the weight will slowly come down. At the same time, turn the minute hand past the quarter hour to see if it will engage the chime. This is the same as making the weight weigh more.

Using cloth gloves, or at least a cloth of some kind, pull down on the weight some.

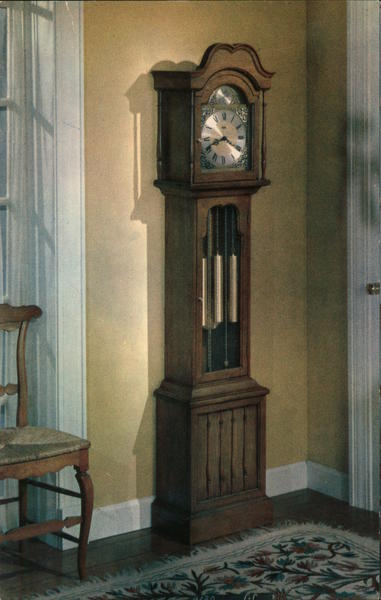

The chime weight is on the right as you face the clock and has the heaviest weight. Never go to the point where the top of the shiny weight cover cant be seen. When winding the weights up make sure the top of the weight can be seen when done. The grandmother and grandfather chain drive units often do not have this feature. Some larger clocks have over wind protection to prevent this. The Grandfather clock weights can get stuck in the high position if over wound.

0 kommentar(er)

0 kommentar(er)